Deferred Maintenance: The Silent Risk Undermining America’s Data Center Boom

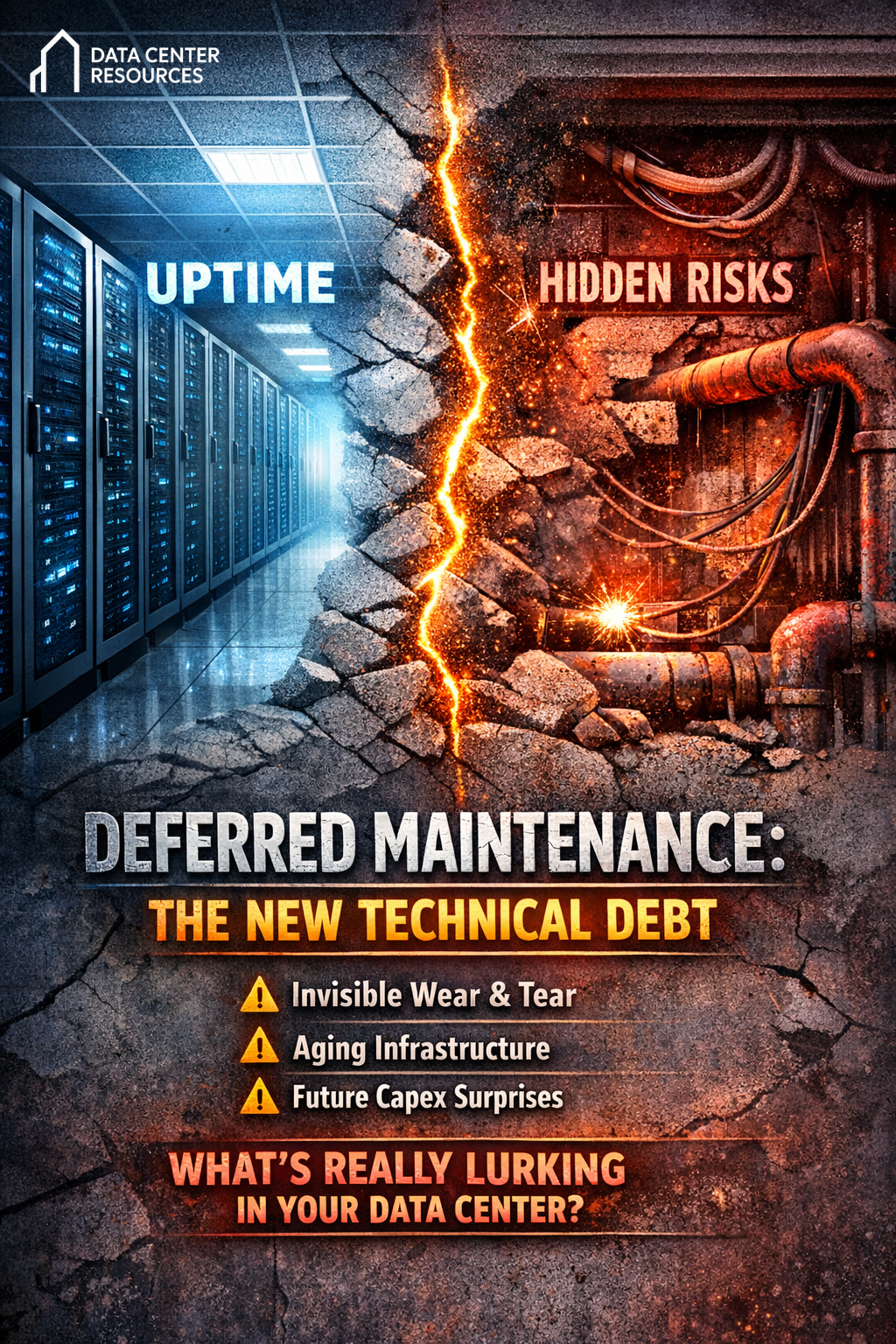

The greatest threat to digital infrastructure isn’t outages, AI demand, or power shortages. It’s the maintenance nobody wants to pay for.

On paper, the facility was flawless.

Five nines of uptime. No major incidents. Clean audit history. Strong utility relationships. The kind of data center that gets toured by investors and referenced in pitch decks as a proof point of operational excellence.

Then, in the middle of an otherwise routine expansion, a contractor noticed something odd while trenching near the substation yard. A grounding conductor one of dozens buried beneath the site showed advanced corrosion. Not catastrophic. Not alarming. Just… wrong for a facility of this age.

Further investigation revealed more. Corroded bonding connections. Improvised fixes layered over older ones. Temporary solutions that had quietly become permanent. None of it had ever triggered an alarm. None of it had ever shown up in uptime metrics. And none of it had ever been flagged as urgent.

Until it was.

What followed wasn’t a dramatic outage or a viral headline. It was worse: months of forensic engineering, unexpected capital expenditures, delayed expansion timelines, insurance scrutiny, and an uncomfortable realization that the facility’s pristine operational reputation had been built on a foundation slowly eroding out of sight.

This is deferred maintenance. And in the data center industry, it has become one of the most pervasive and least discussed systemic risks of the last decade.

The Industry’s Favorite Illusion: Uptime as Health

The data center sector has trained itself to believe that uptime equals integrity.

If the lights stay on, the thinking goes, the system must be healthy. If service-level agreements are met, the infrastructure must be sound. If customers aren’t complaining, there can’t be a problem worth addressing.

This mindset made sense when facilities were simpler, load profiles were predictable, and expansion cycles were measured in decades rather than quarters. It makes far less sense in today’s environment, where hyperscale demand, AI-driven density, and aggressive go-to-market timelines have fundamentally altered how infrastructure ages.

Uptime measures whether a system failed. It does not measure how close it is to failing.

Deferred maintenance thrives in that gap.

It hides in systems that still function but no longer operate within their original design assumptions. It accumulates in components that degrade gradually, silently, and unevenly. It flourishes in environments where the cost of interruption is so high that operators become conditioned to avoid touching anything that appears to be working.

Over time, maintenance becomes reactive. Then selective. Then strategic but not in the way the word is usually meant.

How Deferred Maintenance Actually Starts

Contrary to popular belief, deferred maintenance rarely begins as negligence.

More often, it starts as pragmatism.

A minor issue is identified during a routine inspection. It’s not urgent. It doesn’t affect load. It doesn’t violate code. Fixing it would require downtime, vendor coordination, or budget approvals that feel disproportionate to the risk.

So it’s logged. Deferred. Pushed to the next maintenance window.

Then the next window fills up with higher-priority items. And the one after that gets canceled due to a customer onboarding. And eventually, the original issue becomes background noise something everyone assumes someone else has already addressed.

Multiply that process across thousands of components, dozens of systems, and years of operation, and deferred maintenance stops being a list of small issues. It becomes an operating condition.

One that no single person intentionally created and no single person fully understands.

The Compounding Effect Nobody Models

Deferred maintenance behaves less like a checklist item and more like compound interest.

Each unaddressed issue slightly increases the stress on adjacent systems. Each workaround introduces a new variable. Each undocumented fix reduces the accuracy of as-built drawings and operational models.

Over time, the system drifts.

Electrical connections experience thermal cycling beyond their original tolerances. Mechanical fasteners loosen incrementally under vibration. Grounding resistance changes as soil chemistry evolves. Cooling systems run harder to compensate for minor inefficiencies that no longer register as anomalies.

None of this triggers alarms. None of it violates SLAs. But all of it reduces margin.

Eventually, the facility’s operational buffer the gap between normal operation and failure becomes dangerously thin. When a real disruption occurs, whether it’s a utility event, a load spike, or an expansion tie-in, there’s no slack left in the system to absorb it.

What appears externally as a sudden failure is, internally, the result of years of accumulated deferrals.

Deferred Maintenance as Financial Engineering

In recent years, deferred maintenance has taken on a more sophisticated role one that blurs the line between operations and finance.

For facilities preparing for sale, recapitalization, or refinancing, maintenance decisions increasingly reflect transaction timelines rather than asset lifecycles. Non-critical repairs are postponed to preserve short-term cash flow. Capital expenditures are reclassified or minimized to present cleaner financials.

The asset still performs. The numbers still work. The deal closes.

But the risk doesn’t disappear. It transfers.

This is why buyers with deep operational experience now discount assets not based on uptime history, but on maintenance transparency. They know that a facility with perfect availability but incomplete maintenance records is often more dangerous than one with a documented incident history.

Deferred maintenance becomes a form of technical debt invisible on balance sheets, but very real in future capex requirements.

The Systems Most Likely to Be Ignored

Not all infrastructure ages equally. Some systems are inherently more vulnerable to deferral because their degradation is harder to observe and easier to rationalize.

Grounding and bonding systems top the list. Buried, inaccessible, and rarely tested under real-world conditions, they often escape scrutiny until a fault reveals their weaknesses.

Busways and high-amperage connections follow closely behind. Slight increases in resistance don’t cause immediate problems, but they generate heat, accelerate wear, and reduce long-term reliability.

Cooling distribution infrastructure especially in retrofitted facilities is another common blind spot. As rack densities increase, airflow patterns change in ways original designs never anticipated. Temporary cooling fixes become permanent solutions, gradually eroding system efficiency.

Even fire suppression systems are not immune. Changes in room layouts, cable densities, and airflow can subtly compromise suppression effectiveness without triggering compliance violations.

Deferred maintenance doesn’t target dramatic components. It targets the boring ones. The systems nobody tours. The infrastructure nobody photographs for marketing materials.

Documentation Drift: The Invisible Multiplier

One of deferred maintenance’s most damaging side effects is documentation drift.

As temporary fixes accumulate, as components are swapped without full redraws, and as emergency changes bypass standard processes, the gap between how a facility is documented and how it actually operates widens.

Eventually, no single document accurately reflects reality.

This matters far more than most operators realize.

During expansions, retrofits, or incident responses, teams rely on drawings and models to make rapid decisions. When those documents are wrong, even experienced engineers can make choices that inadvertently compound risk.

Documentation drift also undermines training. New staff learn systems that exist on paper, not the ones they’re actually responsible for maintaining. Tribal knowledge fills the gaps until the people who hold it leave.

At that point, deferred maintenance stops being a technical issue and becomes an institutional one.

The Human Cost of Deferral

Deferred maintenance is often framed as a budgeting problem. In reality, it’s also a human one.

As facilities become more automated and vendor-reliant, in-house technical expertise atrophies. Staff learn how to operate systems, but not how they fail. Preventive maintenance becomes checklist-driven rather than analytical.

When experienced technicians retire or move on, they take with them years of contextual knowledge subtle cues about which systems need attention, which shortcuts are dangerous, and which anomalies matter.

What remains is a facility that appears modern, well-instrumented, and compliant, but lacks the institutional memory required to recognize slow degradation.

Deferred maintenance thrives in that environment. Not because people don’t care, but because no one feels empowered or informed enough to challenge the status quo.

Why Expansion Projects Expose Everything

Nothing reveals deferred maintenance faster than expansion.

Tie-ins stress existing systems. Load increases amplify inefficiencies. Construction activity uncovers buried infrastructure and undocumented modifications.

This is why so many expansion projects run into “unexpected conditions” that derail schedules and budgets. The surprises aren’t random. They’re the physical manifestation of years of deferred decisions.

Utilities, insurers, and permitting authorities are increasingly aware of this pattern. Facilities with unclear maintenance histories face longer review cycles, higher premiums, and stricter conditions.

Deferred maintenance, once seen as an internal operational choice, now has external regulatory and financial consequences.

The Strategic Mistake Most Operators Make

The most common response to deferred maintenance is to treat it as a backlog problem.

Create a list. Prioritize items. Address them over time.

This approach misses the point.

Deferred maintenance is not just a collection of undone tasks. It’s a signal that the organization’s incentives are misaligned with the asset’s long-term health.

Facilities that successfully manage deferred maintenance don’t just spend more. They plan differently. They design systems with maintainability in mind. They document obsessively. They test assumptions regularly. And they accept that some downtime is the cost of preserving future reliability.

Most importantly, they recognize that maintenance is not a cost center it’s a risk management function.

The Facilities That Avoid the Trap

The operators least affected by deferred maintenance tend to share a few characteristics.

They integrate maintenance planning into early-stage design decisions. They favor systems that are easier to inspect, access, and replace, even if upfront costs are higher. They maintain accurate, living documentation that reflects operational reality.

They also treat maintenance transparency as a strategic asset. When selling, refinancing, or expanding, they can demonstrate not just performance history, but infrastructure integrity.

In a market increasingly sensitive to risk, that credibility matters.

The Bigger Picture: Infrastructure at Scale

As data centers become foundational to national economies, deferred maintenance takes on broader implications.

Failures don’t just disrupt individual customers. They affect supply chains, financial systems, public services, and geopolitical competitiveness.

The industry’s ability to scale responsibly depends not just on building faster, but on maintaining smarter.

Deferred maintenance is the shadow side of rapid growth. Ignoring it doesn’t make it disappear. It just ensures that its eventual consequences will be more expensive, more disruptive, and more public.

Designing for What Comes After Day One

The irony of deferred maintenance is that it’s often born from success.

Facilities that operate reliably feel less urgency to intervene. Growth pressures reward speed over thoroughness. Capital markets favor expansion narratives over maintenance stories.

But infrastructure doesn’t care about narratives.

It responds to physics, chemistry, and time.

The operators who will define the next era of data center development are not the ones who build the fastest, but the ones who design for what comes after the ribbon-cutting for decades of operation, adaptation, and change.

Deferred maintenance is not a failure of execution. It’s a failure of foresight.

And in an industry built on long-term reliability, that may be the most dangerous failure of all.

About the Data Center Resources

At Data Center Resources, we work at the intersection of land, power, permitting, and infrastructure strategy helping developers and operators design facilities that remain resilient long after day one. Because in data centers, what you maintain matters just as much as what you build.

If you’re planning expansion, recapitalization, or new development, the real question isn’t how fast you can build it’s how well the infrastructure will age.